BNSF’s safety goal of an accident and injury-free workplace is becoming more possible—with the help of artificial intelligence (AI).

BNSF is utilizing AI technology to detect wheel defects, in which algorithms sort through more than 35 million readings a day to identify potential issues that could lead to derailment and other issues on our tracks. It helps maintenance crews identify the urgency of repairs and spot trends that indicate when maintenance should happen.

A newer use of AI that BNSF is using is our Machine Vision System (MVS)— technology that combines images of equipment with sophisticated data analysis to identify defects before they lead to larger problems, such as an equipment failure or derailment. MVS helps us keep an eye on the tracks at all times.

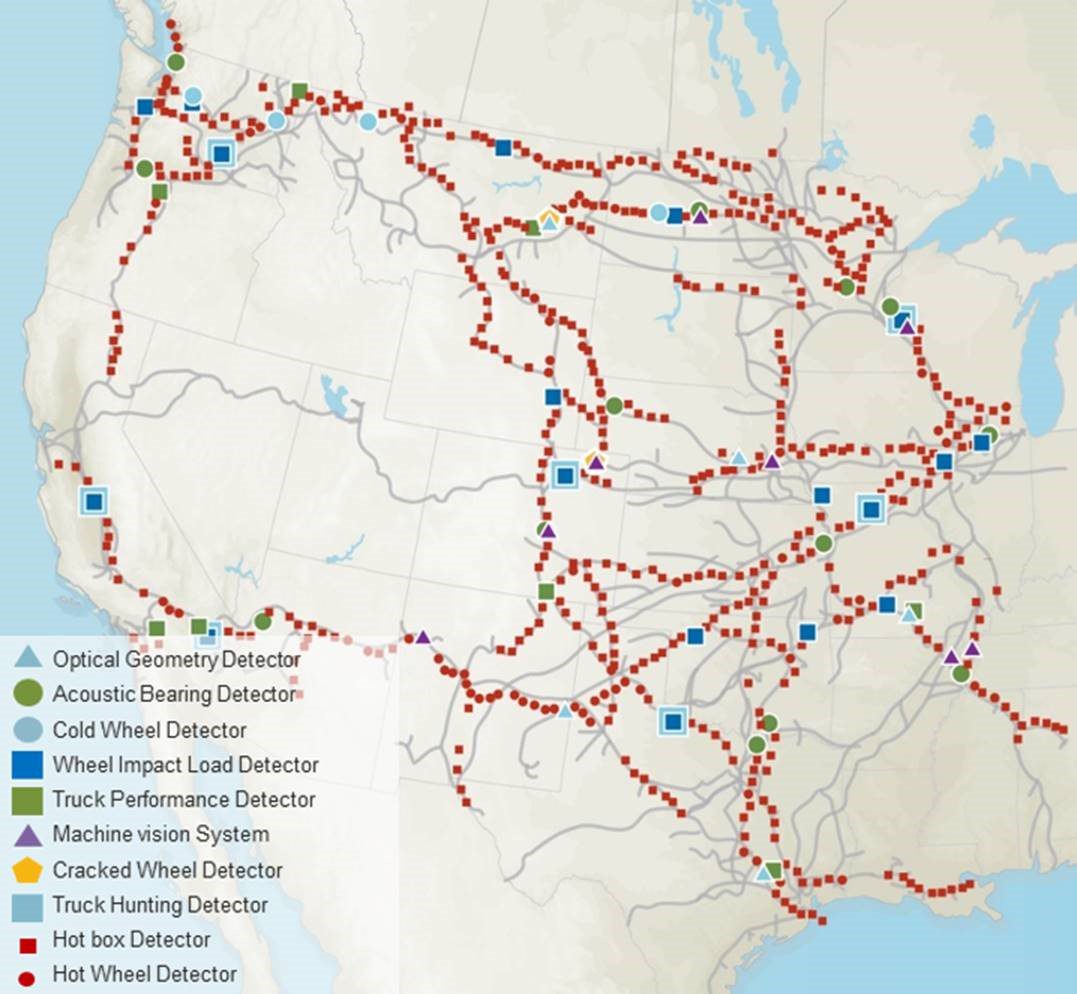

BNSF’s first-generation MVS technology was added to our network starting in 2006. Our network now includes more than 70 systems at 15 locations, targeting a variety of car components and defects.

Seven Machine Vision detectors have been implemented across the network in the past five months. These systems have been installed at high-volume, high-density locations along our main lines. About 250 trains pass the detectors daily, and each train produces about 3,000 images of wheels—750,000 images daily. Photos of potential defects are then manually reviewed by our crews.

The seven detectors have found more than 20 broken or cracked wheels over the past five months, meaning that the technology has helped BNSF prevent 20 potential derailments. Find out more about BNSF’s use of AI: bit.ly/2JGOZ6W.